|

BALANCING OF

ROTATING EQUIPMENT COMPONENTS

|

To give an

overall idea about the balancing of Rotating Equipment components to the

Maintenance and Operations personnel.

Scope:

The scope of the manual is

to explain the purpose of balancing the rotating equipment components and to

give a brief information about the balancing procedures, balancing machines and

the prevalent balancing standards.

Terminology

1.1 Balance Quality Grade: G Xxx

1.2 Center Of Gravity

1.3 Principal Inertia Axis

1.4

Correction Plane (For Balancing)

1.5 Static Unbalance

1.6 Couple Unbalance

1.7 Critical Speed

1.8 Dynamic Unbalance

1.9 Rotor

1.10 Rigid Rotor

1.11 Flexible Rotor

1.12 Specific Unbalance

1.13 Residual

Unbalance

1.14 Permissible Residual Unbalance (U per

)

1.15 Units Of Unbalance Introduction

2.1 Reasons For Balancing

2.2 Causes Of Unbalance

3 Safety & Environmental Precautions

3.1 Safety Of The Balancing Machines

3.2 Safety While Balancing The Rotors

3.3 Safety

During The Field Balancing Of The

Rotating Equipment :

4 BALANCING

MACHINES:

4.1 Gravity Balancing Machines:

4.2 Centrifugal Balancing Machines:

4.2.1 SOFT BEARING

BALANCING MACHINES

4.2.2 HARD BEARING

BALANCING MACHINES :

5 BALANCING METHODS

5.1 Preparation For Balancing

5.2 Shop Balancing

5.2.1 SYMMETRICAL ROTOR

5.2.2 SYMMETRICAL ROTOR

WITH OUTBOARD BALANCING PLANES –

5.2.3 OVERHUNG AND NARROW

ROTORS

5.3 High Speed Balancing –

5.4 Field Balancing-

6 BALANCING STANDARDS.

References

1 Terminology

1.1 Balance Quality Grade: G Xxx

For rigid rotors, G , is the product of specific unbalance , e, and rotor maximum service

angular velocity. Service angular velocity is nothing but the service RPM

expressed in radians per second.( w )

G = e * w

1.2 Center Of Gravity –

The point in a body of a rotor through which the

resultant of the weights of its component particles passes for all orientations

of the body with respect to a gravitational field is called the center of

gravity - C.G.

This can also be described as the point about which

the rotor’s weight is equally distributed.

1.3 Principal Inertia Axis –

A line about which the rotor weight is equally

distributed is known as Principle Inertia Axis ( PIA in short ) . It is obvious

that the Center of Gravity ( CG ) is

always on the Principal Inertia Axis ( PIA )

1.4 Correction Plane (For Balancing)-

The plane perpendicular to the shaft axis of a rotor

in which correction for unbalance is made. The correction can be in the form of

material addition, or material removal, or any change in the weight

distribution in this plane.

1.5 Static Unbalance

It is that condition of unbalance for which the central

principal axis is displaced only

parallel to the shaft axis.

1.6 Couple Unbalance

It is that condition of the unbalance for which the

central principal axis intersects

the shaft axis at the center of gravity.

1.7 Critical Speed

It is that speed at which a system resonance is

excited. The resonance may be of journal supports ( rigid mode ) or flexure of

the rotor ( flexural mode ). There are many critical speeds for a rotor and

they are denoted like first, second, third in lateral and torsional modes.

1.8 Dynamic Unbalance

It is that condition of unbalance for which the

central principal axis ( PIA ) is not

parallel to and does not intersect the shaft axis. Obviously the CG is

not on the shaft axis as well .It is usually a combination of the static and

couple unbalance. This is the type of unbalance, which is usually found in

practice in the unbalanced rotor.

The Dynamic unbalance is

equivalent to two unbalance vectors in two specified planes, which completely

represent the total unbalance of the rotor.

Dynamic unbalance may also be

resolved into a static and couple unbalance vectors whose vector sum is also

equal to the total unbalance of the rotor.

1.9 Rotor

A body capable of rotation, which generally has journals

supported by the bearings.

1.10 Rigid Rotor

A rotor is considered rigid if its unbalance can

corrected in any two correction planes. After the correction, the residual

unbalance does not change significantly at any speed up to the maximum service

speed. In other words it also means that the rotor service speed is much lower

than its first lateral critical speed.

1.11 Flexible Rotor

A rotor that does not satisfy the definition of the

rigid rotor is known as a flexible rotor. It also means that the rotor needs to

be balanced in such a way that it remains reasonably balanced while it attains

the maximum service speed. The rotor of this class runs at least above the

first lateral critical speed. While passing through the critical speeds there

is some amount of elastic deflection depending on the mode shapes. The

correction planes are so selected that, the elastic deflection has no severe

impact on the balance of the rotor, at that speed range.

1.12 Specific Unbalance

The static unbalance U divided by the rotor mass M.

This will also yield the value for mass eccentricity, which is denoted by “ e “

1.13 Residual Unbalance

The unbalance of any kind that remains after the

balancing of the rotor is known as residual unbalance. This must be less than

the permissible value, as per the balancing standers adopted for that class of

rotor.

1.14 Permissible Residual Unbalance (U per )

The maximum residual unbalance permitted for a rotor

or for a correction plane for the rotor is termed as permissible residual

unbalance. This is expressed as

U per = e per x m , Where m is

the mass of the rotor.

1.15 Units Of Unbalance

Unbalance is measured in

gram-millimeters or ounce inches. It simply means the quantity of unbalance

mass (m) , multiplied by the distance (

R ) from shaft axis.

As an example, an unbalance of 15

gm at 100 mm radius will introduce an

unbalance of ( 15 x 100 ) = 1500 gm-mm ,

in that plane.

This is independent of speed of

rotation. However the same unbalance will produce higher centrifugal force if

the speed of rotation increases. In fact the centrifugal force generated due to

unbalance is proportional to the “ square “ of RPM. ( F =

m x R x W x W)

2 Introduction

One of the basic problems in

the rotating machinery is the unwanted vibration. Since the rotor rotates, if

it is out of balance, vibration will be present primarily because of the

unbalance. This can corrected by balancing the rotor. There are many other

reasons for balancing the rotors.

2.1 Reasons For Balancing

An unbalanced rotor will cause

vibrations, and may result into premature bearing failures, seal failures,

noisy operation, shaft & coupling damage, structural vibrations and

failures. This depends on the degree of unbalance and also the tolerance of the

various components to theses forces produced due to unbalance. Therefore balancing of the rotor is required

for the following reasons-

Ø

Reduce stresses on the

rotor shaft, bearings, coupling, gears, frame, foundations, adjoining structure

and machinery, etc.

2.2 Causes Of Unbalance

Ideally speaking, a fully

machined (from outside and inside) and absolutely symmetrical rotor should

be inherently balanced in the “ as machined ” condition, even if it is not “

balanced “ after manufacturing. However this is rarely achieved. The reasons

are as follows-

Ø Anisotropy of the material due to voids in casting, inclusions

and blowholes in the welding, metallurgical differences, and so on.

Ø Geometrical differences resulting in non- symmetry

Ø Distortion during operation because of mechanical forces,

thermal distortion, looseness at higher speeds due to centrifugal forces

Ø Corrosion, erosion and the deposits on the rotating parts in

service

3 Safety & Environmental Precautions

3.1 Safety Of The Balancing Machines :

The balancing machines handle

rotating components like rotors of pumps, turbines and compressors. The lifting

and shifting of these parts should be done by qualified trained personnel and by

using the load tested lifting equipment like cranes, slings, eyebolts and

shackles.

When the rotors are balanced,

they are rotated at a certain speed. The area around the machine should be well

cordoned and should be kept safe for the personnel working nearby. The rotor

should be thoroughly checked for any loose part or the damage so as to exclude

any possibility of loose part on the rotating component.

Please see the photograph of the

Balancing Machine equipped with the safety barriers and the enclosure, for the

safety.

The rotor has to be coupled very

carefully with the balancing machine coupling. The error at this point results

in a faulty balancing and a chance of rotor getting uncoupled while being

rotated in the balancing machine.

Every balancing machine has a

safe working limit as far as the maximum speed and the maximum weight of the

rotor it can safely handle. The balancing machine should be strictly used

within this limit. Exceeding the limit may result in damage to the machine,

rotor and the personnel operating the machine, etc.

3.2 Safety While Balancing The Rotors :

The unbalance correction usually carried out by adding or

removing the mass on the rotor. The addition of the mass can be achieved by

welding, bolting, riveting etc. This operation should be performed using all

the PPEs (personal protective equipment) like hand gloves, welder’s glasses and

face shields, etc.

The mass can be removed by grinding, machining etc. The

appropriate PPEs life, face shields, hand gloves, etc must be used. Secondly,

if the correction is done, while the rotor is still on the rollers of the

balancing machine, it should be positively ensured that the machine does not

start spinning the job accidentally.

A care must be taken to remove the mass gradually as per

the recommended practices and keep the strength and integrity of the rotor in

mind while doing any such operations. The addition of mass or removal of mass

should not result in weak spot or should not cause a major disturbance to the

flow in the equipment.

3.3 Safety During The Field Balancing Of The Rotating Equipment :

Some of the large and slow speed rotors like boiler fans,

conveying blowers, and Cooling tower fans, etc are balanced at site for

convenience. The equipment is run for a short time to take the vibration and

phase readings. The correction is made in steps by adding the mass at a

specific radius and angle. Extreme care is necessary while adding the masses

and also while taking the readings. Usually three or even more trials are necessary

in the field balancing. After every trial followed by correction on the rotor

the equipment is started for taking the readings. Under no circumstances the

equipment should accidentally start when the job is being carried out on the

rotor.

The addition of the mass can be achieved by welding,

bolting, riveting etc. This operation should be performed using all the PPEs

(personal protective equipment) like hand gloves, welder’s glasses and face

shields, etc. Proper work permits, hot work permits and positive isolation of

the equipment while the weights are being added on the rotor must be strictly

followed. All the concerned personnel should be informed before starting the

job and also after completing the balancing job.

4 BALANCING MACHINES:

The purpose of the

balancing machine is to determine the magnitude and angular position of the unbalance in the plane of

reference called the balancing plane.

4.1 Gravity Balancing Machines:

This type of machine includes the Horizontal

ways, knife-edges and the roller stand. The rotor to be balanced is placed on

it and rolled slowly so that the heavy side rolls down due to gravity. This

machine is good enough only to detect the static unbalance and useful for

narrow rotors only. This is a useful step for the subsequent dynamic balancing,

because the statically balanced rotor with a reduced residual unbalance is easy

to balance on the dynamic balancing machines.

4.2 Centrifugal Balancing Machines:

The rotor is supported by the

balancing machine bearings and rotated around a horizontal or vertical axis.

The centrifugal balancing machine is capable of measuring the static unbalance

(single plane) and static or couple unbalance (in two-plane machine). It should

be noted that only a two plane rotating balancing machine can detect a couple

and hence a dynamic unbalance. In these types of machines, the amplitude and

phase of motions or reaction forces of rotating centrifugal force vector is

sensed and measured and also indicated to the operator for the balance

correction.

Two types of the centrifugal

balancing machines are commonly used. They are called soft bearing machines and

the hard bearing machines.

4.2.1 SOFT BEARING BALANCING MACHINES

The name “ soft bearing balancing

machine “ is derived from the fact that these machine support the rotor to be

balanced on the bearings which are very flexible. This allows the rotor and

bearing pedestals to vibrate freely and generously in the direction

perpendicular to the rotor axis. The resonance of the rotor system occurs at a

speed much lower than the speed at which the actual balancing is carried out.

Please refer the ”Phase angle and displacement amplitude versus rotational

speed in the SOFT BEARING balancing machines” given below.

Phase angle and displacement amplitude versus rotational

speed in the SOFT BEARING balancing machines

DETAILS OF VARIOUS COMPONENTS OF THE BALANCING

MACHIUNES

HEIGHT

ADJUSTABLE ROLLER CARRIAGE FOR ROTOR WITH THEIR OWN JOURNALS

SLEEVE

BEARING SUPPORT FOR THE HIGH SPEED BALANCING OF ROTOR

4.2.2 HARD BEARING BALANCING MACHINES :

Hard bearing balancing machines are similar to the soft

bearing balancing machines in construction. The only difference being their

bearing supports are much stiffer in comparison. This results in a resonance of

the rotating system occurring much above the balancing speed. The hard bearing balancing

machine is therefore specially designed to be operated well below the resonance

.

Phase angle and displacement amplitude versus rotational

speed in the HARD BEARING balancing machine

Basically there are three types of balancing jobs encountered

and the methods involved used for those types may be categorized as

Shop balancing

High Speed balancing

Field balancing

BALANCING

A ROTOR ON A BELT DRIVEN

BALANCING MACHINE

A VERY BIG FAN ROTOR BIENG BALANCED

A BIG , VERY

HEAVY STEAM TURBINE ROTOR BEING BALANCED

5.1 Preparation For Balancing

Before starting the balancing of a rotor few things are

important to remember. The list is very long but some of the important points

are highlighted below-

If the rotor to balanced is the one which was used in

service, clean the rotor thoroughly and inspect for any damage, cracks, wear

etc. A thorough degreasing followed by ash blasting or ceramic bead blasting is

an ideal way to clean the rotor.

In case of a doubt, magnetic particle inspection or Dye

Penetration test is helpful in determining the surface & subsurface flaws

and cracks etc.

It is always a good idea to remove all the deposits,

especially polymer deposits and the deposits on fan rotors, turbine blades,

before balancing.

The straightness of the rotor shaft must be checked and

the ovality, taper and wear on the

journals must be measured. If the shaft is bent and the journals are not within

the specified accuracy, there is no use of balancing in this case. These faults

must be corrected first to achieve the accurate balancing.

The rotor assembly and fitment of the impellers and discs

on the shaft must be checked for proper

shrink fits, perpendicularity and axial location. No rotating part

should be loosely installed on the shaft.

It is also important to measure the radial and axial

runouts on the impeller discs and shrouds. This has to be within the limits

specified. Any correction or machining required has to be done before the

balancing. After balancing no corrections are possible .

The rotor is balanced by supporting the journals on the

balancing machine rollers. Hence both the journals of the rotor as well as the

rollers of the balancing machine have to be inspected and should be free of

inaccuracy.

The compressor, fan and pump rotors must be balanced on

the balancing machine by rotating them in their usual direction of rotation.

Where as the turbine rotor is reverse rotated while balancing.

The rotor to be balanced must be a full assembly including

the keys, the coupling half , any subassemblies like overspeed mechanism, lube

oil pump driving gear and so on. This ensures that the full rotating assembly

is precisely balanced as one single unit in the final balancing step.

5.2 Shop Balancing

Most of the rotors are balanced

in the shop where they are manufactured. The Original Equipment Manufacturers

who manufacture pumps , turbines and compressors , carry out the balancing of

their rotors by this method. Depending on the size, weight and the speed of the

equipment, different types of the balancing machines are used. In most of the

cases the speed used to rotate the rotor is much less than the actual speed of

the rotor. Depending on the shape of the rotor different methods are employed.

Some of the shop balancing machines have direct drives and the rotor to be

balanced is connected by a suitable end drive adapter, which connects the rotor

to the driver by a universal joint. In some of the balancing machines, the

drive is by a belt for spinning the rotor, as shown on the Universal Balancing

machine on the previous page.

For balancing the rotor the

important dimensions like the bearing span ( D), distance between CG and the

correction planes ( BL & BR ), distance between bearing and the correction

plane ( A ) must be measured and noted carefully.

5.2.1 SYMMETRICAL ROTOR

The type of rotor that falls

under this category must satisfy the following conditions

·

Correction planes are

within the bearings

·

The distance “B” is greater

than 1/3 of “ D”

·

The correction planes are

equidistant from the center of gravity CG and when the correction planes are

not equidistant from the CG, the permissible unbalance calculated per plane

should be in that proportion.

U per Left = U

per ( BR / B )

U per Right

= U per

( BL / B )

This type of rotors are typically seen in double entry boiler fans

etc. Please see the following figure.

5.2.2 SYMMETRICAL ROTOR WITH OUTBOARD BALANCING PLANES

These

type of rotors are also popularly known as “ Dumb-bell” rotors.

The correction planes are

equidistant from the center of gravity CG and when the correction planes are

not equidistant from the CG, the permissible unbalance calculated per plane

should be in that proportion.

U per Left = U per ( BR / B )

U per Right = U per ( BL / B )

This

type of rotors is typically seen in turbo-expanders, integral gear air

compressor rotors and so on.

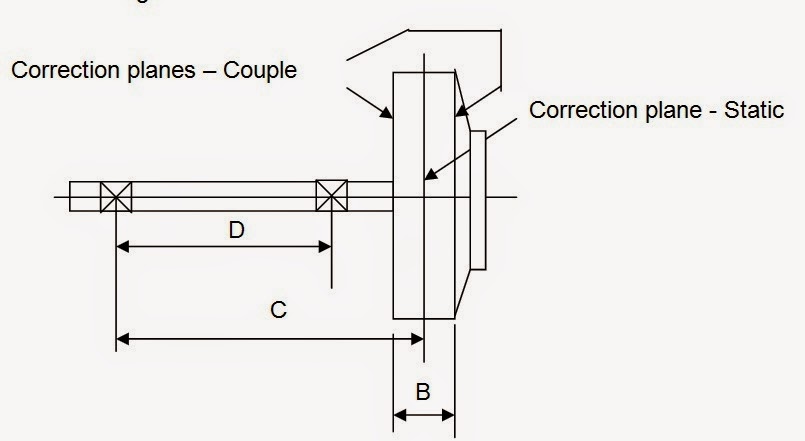

5.2.3 OVERHUNG AND NARROW ROTORS

These

are very common for the overhung fans and overhung pump impellers. These types

of rotors are supported by two bearings and as compared to the impeller

diameter the width of the impeller is very small making it a narrow rotor.

The

following rules and conditions apply to the overhung and narrow rotors.

The

distance between the correction planes is less than 1/3 the distance between

the bearings. ( B < 1/3 D.)

The

permissible dynamic bearing loads are assumed to be equal.

Couple

corrections are made 180 degrees apart in their respective planes.

The

plane for static corrections may be a third plane or either of the planes used

for couple corrections.

Allocate per as static and couple residual unbalance

as follows :

U per Static = U per / 2 * D / 2*C

U per Couple

= U per / 2 * 3*D / 4*C

Permissible

unbalance allocation for overhang and narrow impellers require that two-plane

unbalance correction divided into static and couple unbalance equivalents.

5.3 High Speed Balancing

The

high speed balancing or “ at speed

balancing “ is done for high speed critical centrifugal compressors and

turbines etc. It requires a very sophisticated set up and a balancing machine.

These types of facilities are limited in number worldwide and they are very

expensive as well.

The

installation consists of a chamber capable of holding the rotor along with the

bearing pedestals, and also a place for the balancing personnel to move inside

for weight correction on the same rotor by machining, grinding, etc. The

complete set up is in a bunker and the in an airtight chamber or enclosure. The

chamber is connected to the vacuum pumps. The vacuum is maintained to avoid the

airflow through the impeller. At very high speed the windage and friction will

be very disturbing, and dangerous as well. Secondly it will require a prime

mover of very high horsepower to spin the rotor at that speed. One more problem

will be the heating up of the air inside the chamber. Rotating the rotor in a

vacuum chamber solves all these problems. There are protection devices to

safeguard against the vacuum failure.

Normally a variable speed drive or

motor and gearbox combination is used. The balancing equipment are also very

sophisticated and they include computerised system which calculates the

unbalance and the angular position etc. It records the initial unbalance and also

records all the stepwise corrections. It is worth noting that for balance

correction, say by grinding, the rotor must be stopped and vacuum must be

relieved. Again after the correction, the rotor must be tested in re-evacuated

chamber. This makes the High Speed balancing a very time consuming, labour

intensive and expensive operation.

It

must be noted that all the rotors do not deserve such a stringent testing. The

multistage, critical rotors, falling in the category of “ Flexible Rotors”, meaning operating above

their first lateral (bending) critical speed, must be tested this way. This

testing revels characteristics of the dynamic rotor response.

Please

refer to the following pictures showing a complete set-up for high speed

balancing. Note the enclosure, the bearings with pickups and the vacuum seals,

etc. On these types of machines the critical multi-impeller rotors are also

tested for what is popularly known as “

Over Speed Testing “.

5.4 Field Balancing

This

is one more practical way of balancing the rotating equipment and the name of

this method is due to the fact that it is done in the field. This is

also suitable for big rotors rotating at lower speeds for example air blowers,

fans, etc. Generally this method is used for small finer corrections and not

the major adjusting. This is usually done when the machine vibrations show an

increase and the cause is the imbalance. The rotors such as ID fans show “ out

of balance “ after some use due to thermal distortion, corrosion, erosion, wear

and tear and deposits etc. If the imbalance resulting due to such a problem is

not very high, it can be corrected easily by “ field balancing”. It is much

easier to do a field balancing than, de-coupling, opening the equipment, and

taking out the complete rotor assembly, transporting from site to balancing

facility and then fixing back the same way after the shop balancing.

Secondly,

many of the equipment are so designed that a “ field balancing” provision is

made on the rotor. Electric motors, air fan rotors, and sometimes even the

steam turbines have a provision for adding the balance correction weights without

removing the rotor from the casing. The end covers have widows to get

access to the balance correction ring or slots in which the balance weights are

added and fixed permanently so that they do not move in service.

In

the field balancing, single plane, two-plane and multi plane balancing is

possible. It depends on the shape of the rotor and the running speed. Very

narrow overhung type rotors are balanced in the single plane. Relatively broad

rotor life ID fan rotors and electric motor rotors are balanced in two planes.

Example

of a single plane field balancing, showing measurement points

As

a preparation for the field balancing of the rotor it is essential to verify

that the cause of the vibration is unbalance. After this is confirmed, it is a

god idea to inspect the rotor for any major damage. If the rotor is coated with

dirt and dust or some polymer deposits, it is essential to clean the rotor.

High-pressure hot water cleaning is one of methods to clean at site. Then some

field dimensions like bearing span (D), correction plane and CG ( BL & BR )

, correction radius (R), correction planes and bearings ( A ) etc are required,

to calculate correction weights.

Example of a two - plane field balancing,

showing measurement points

The field balancing is done by using many different equipment. There are some

portable field balancing equipment available. They have portable vibration

pickups and strobe light. The vibration measure provides an indication of the

unbalance mass and the reading is in proportion of the unbalance.

The vibration

magnitude indicated by the equipment may be displacement, velocity or

acceleration depending on the type of transducer and the selected unit of

display.

As

indicated in the two previous examples, the pickup is mounted on the bearing

housing to measure the vibrations. The angle of unbalance can be found out if

there is a shaft “ key “

which is used to trigger the strobe. Other wise optical pickup is also

used to determine the angle.

Second

possible way is to use the “three trial runs “ method. The first run is take in

the rotor in “ as it is “ condition. The vibration amplitude and the phase are

measured. In the second trial a “ suitable trial weight” is attached to the

rotor and the rotor is brought to the operating speed again.

This time the

vibration amplitude and the angle is noted. Then based on these two readings,

the exact balance correction weight is found out and attached. The third run is

usually is a final run and it is expected that the rotor is balanced at this

stage. The vibration levels are within the permissible level. Occasionally a last

“ trim balancing “ is carried out if necessary.

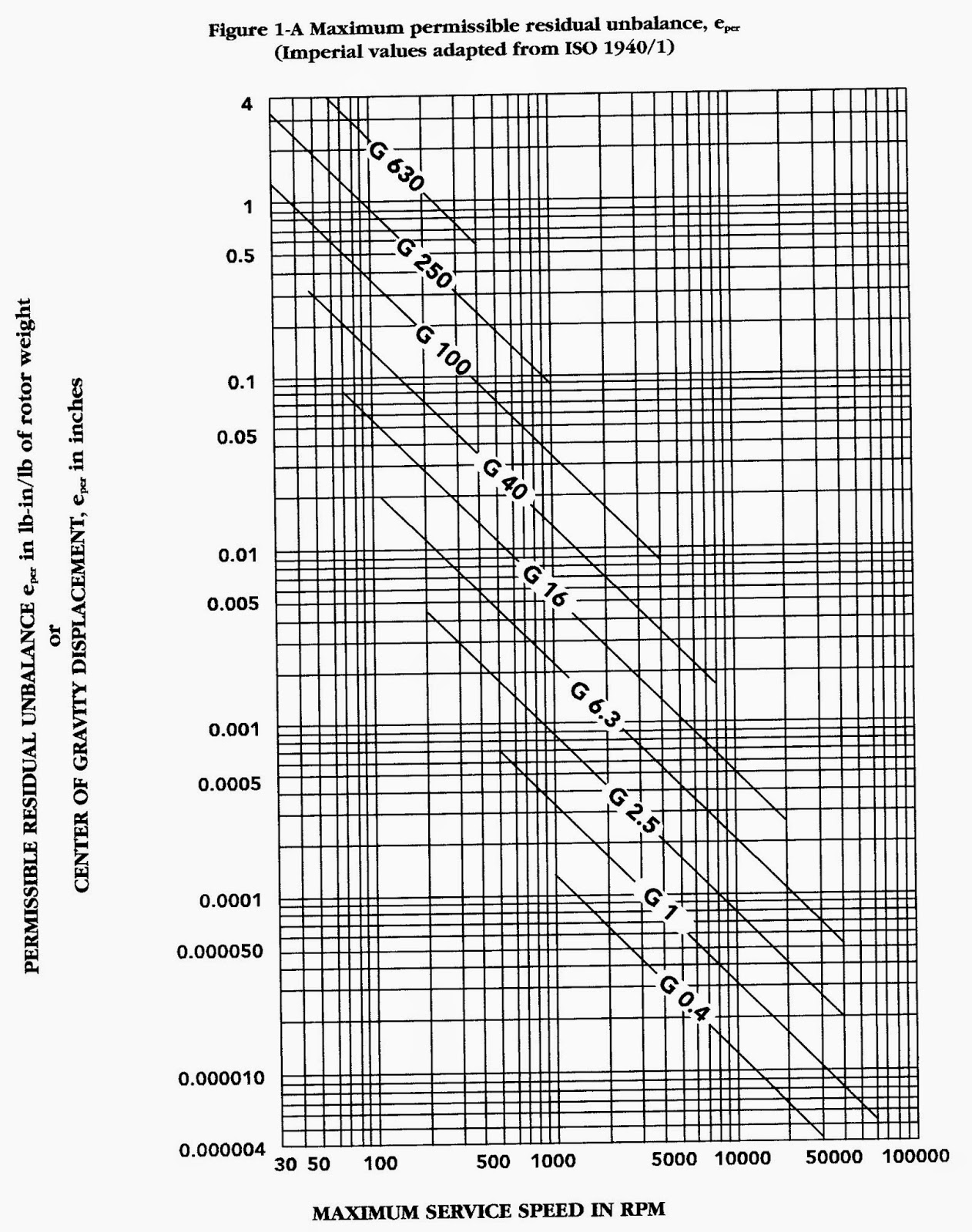

6 BALANCING STANDARDS.

There are many

standards available today, which give guidelines for balancing. One can easily

determine the allowable limits from these standards. One of the most commonly used standard is ISO-1940. This gives the values of Balance Quality

Requirements of the Rigid Rotors.

To use this

standard one must know what type of

rotor is to be balanced. See the Table 1

for determination of the type of rotor. From this table the second thing to

note is the grade. For example

centrifugal pump impellers, and flywheels fall under G 6.3 grade. The steam and gas turbine rotors

and turbo compressor impellers are under grade G 2.5. After selecting the grade

from table 1, next step is to go to Figure

1-A or Figure 1 – B, to find the

maximum permissible residual unbalance e per .

As an example, we

have a centrifugal compressor rotor of weight 2200 lb. weight. The maximum

operating speed is 5000 RPM. The grade

as per table 1 is G2.5. Then the formula become

U per = ( G * e per * weight of rotor / 2 ) Max cont. RPM

= ( 2.5 * 6.0 * 2200 / 2 ) / 5000

= 3.3

oz-inch

If we use the

formula given in API - 617, the

formula is

U per = 4 W / N ,

where W = total rotor weight in lbs. and

N = Max Continuous operation

RPM. Applying this formula to the

previous example, we get

U per = 4 W / N = 4 *

2200 / 5000 = 1.76 oz – inch.

Obviously API - 617 standard is more stringent,

as it allows a smaller permissible unbalance of 1.76 oz-inch compared to the 3.3

oz-inch allowed by ISO -1940.

The other API standards also specify the

similar things as far as dynamic balancing of the rotors is concerned. The

allowable residual unbalance per plane as specified by different API standards

is tabulated as follows-

|

S.N.

|

API STD .

|

APPLICABLE FOR

|

FORMULA

|

|

1

|

API 611

|

Gen. Purpose

Steam Turbines

|

U max = 4 W / N

|

|

2

|

API 616

|

Gas Turbines

For Refineries

|

U max = 4 W / N

|

|

3

|

API 6 17

|

Centrifugal Compressors

|

U max = 4 W / N

|

|

4

|

API 610

|

Centrifugal

Pumps for Petroleum , gas etc

|

U max = 4 W / N

|

Where Umax = residual unbalance in

ounce-inches ( gram-millimetres in SI )

W = Journal static

weight load in pounds ( kilograms in SI )

N =

maximum continuous speed in revolutions per minute RPM.

The above formula

for SI units is expressed as , U max = 6350 W / N

TABLE 1 : BALANCE

QUALITY GRADES & THE ROTOR TYPES ,

ISO 1940

|

Balance Quality

Grade

|

Product of

E per * W

|

ROTOR TYPES –

GENERAL EXAMPLES

|

|

G 4000

|

4000

|

Crankshafts/

drives of rigidly mounted slow ( where the piston speed is less than 9 m/s )

marine diesels with uneven number of cylinders.

|

|

G 1600

|

1600

|

Crankshafts/

drives of rigidly mounted two-cycle

engines.

|

|

G 630

|

630

|

Crankshafts/

drives of rigidly mounted large four-cycle engines and Crankshafts/ drives of

elastically mounted marine diesel engines.

|

|

G 250

|

250

|

Crankshafts/

drives of rigidly mounted fast( where

the piston speed is more than 9 m/s ) four cycle diesel engines

|

|

G 100

|

100

|

Crankshafts/

drives of fast diesel engines with six or more cylinders. And complete

engines for cars, trucks, etc

|

|

G 40

|

40

|

Car wheels,

wheel rims, wheel sets, drive shafts,

Crankshafts/

drives of elastically mounted fast four-cycle engines with six or more

cylinders.

Crankshafts/

drives of engines of cars, trucks, etc

|

|

G 16

|

16

|

Drive shafts (

propeller shafts, cordon shafts with special requirements ) ,

Parts of

crushing machines, agricultural machinery, individual components of engines

for cars, trucks, etc.

|

|

G 6.3

|

6.3

|

Parts of the

process plant machines Centrifuge drums, paper machinery rolls, print rolls,

fans, flywheels, assembled aircraft

gas turbine rotors, , pump impellers, machine tool and general machinery

parts, medium and large electric armatures, small electric armatures

|

|

G 2.5

|

2.5

|

Gas and steam

turbines, rigid turbo generator rotors, turbo compressors, machine tool

drives, medium and large electric armatures with special requirements,

turbine driven pumps

|

|

G 1

|

1

|

Tape recorder

and phonograph drives, grinding machine drives

Small electric

armatures with special requirements

|

|

G 0.4

|

0.4

|

Spindles, discs

and armatures of precision grinders,

Gyroscopes

|

Note : W = 2

p N / 60 rad / sec.

SUMMARY

ON API STANDARDS FOR BALANCING ASPECT

: -

API 617 For Centrifugal Compressors

specifies the following guidelines.

Ref. Para 2.9.5.1: - Major parts of the rotating

element, such as shaft, balancing drum, and impellers shall be dynamically

balanced. When a bare shaft with a single keyway is dynamically balanced, the

keyway shall be filled with a fully crowned half-key. The initial balance

correction to the shaft shall be recorded. A shaft with keys 180 degrees apart

but not in the same transverse plane shall also be treated as described above.

Ref.

para 2.9.4.3: - The rotating element shall be multiplane dynamically balanced

during the assembly. His shall be accomplished after adding no more than two

major components. Balancing correction shall be applied only to the elements

that are added. Other components may require minor corrections during the final

trim balancing of the completely assembled element. On rotors that have single

keyways, the keyway shall be filled with fully crowned half-key. When

specified, the weight of all half keys used during the final balancing of the

assembled element shall be recorded on the residual unbalance worksheet. The

maximum allowable residual unbalance per plane ( journal ) shall be calculated

as follows; -

U max

= 4 * W / N ( and

in SI units U max = 6350 W / N )

Where Umax = residual unbalance in

ounce-inches ( gram-millimetres in SI )

W

= Journal static weight load in pounds ( kilograms in SI )

N

= maximum continuous speed in revolutions per minute RPM.

When spare rotors are supplied they shall be

dynamically balanced to the same tolerance as main rotor.

Ref.

Para 2.9.5.4 – High speed balancing ( balancing in the high speed balancing machine at the

operating sped ) shall be done only with the purchaser’s specific approval. The

acceptance criteria for this balancing shall be mutually agreed upon by the

purchaser and the vendor.

The other standards like API : 610-for pumps,

API :611 – for steam turbines, API : 672

– packaged integrally geared compressors, etc also provide similar guidelines.

7 References

ISO 1940 –

Balance Quality Of Rotating Rigid Bodies – classifies all rigid rotors and

recommends balance tolerances for them.

API STANDARD 610 - Centrifugal Pumps For Petroleum , Heavy Duty

Chemical, And Gas Industry.

API STANDARD 611- General Purpose Steam Turbines

For Refinery Services.

API STANDARD 616 – Gas Turbines for Refinery

Services.

API STANDARD 617 - Centrifugal Compressors For Petroleum , Chemical, and Gas Service

Industry.

Machinery

Component Maintenance and Repair by Heinz P Bloach & Fried K. Geitner –

Gulf Publishing.

Compressors

Selection & Sizing –By Royce N. Brown – Gulf Publishing Company.

Hard – Bearing

Balancing Machines – SHENCK RoTec GmbH.

PGW- Turbo

Compressors for the Process Industry – Pumpen- und Geblasewerk Leipzig GmbH.

2 comments:

“As a military family, we are very thankful for Mr Lee professional service. he was attentive, knowledgeable and took his time to walk us through the loan process. We were informed in a timely manner of any pertinent details we needed to take into account. He was very approachable, understanding and trustworthy. We can’t thank him enough for his excellent service. We highly recommend his and feel blessed to have had his loan assistance to enable us have our home purchase. Military and non military families, Mr Lee you would want to work with for your home purchase & any kind of loan asistance!”

Mr Lee Loan Officer Contact Details:WhatsApp : + 1-989-394-3740E-Mail: lfdsloans@outlook.com

Great tips regrading shrink machine . You provided the best information which helps us a lot. Thanks for sharing the wonderful information.

Post a Comment